At T&R Welding Systems, delivering precise, high-quality work on time and within budget is the key to our success. We employ a workforce that is highly experienced and has been with us for many years. When combined with the latest equipment, few shops can compare with our ability to manufacture the finest production welding.

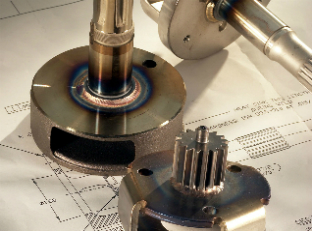

Starting with complete in-house capacity to machine small parts with our horizontal machining centers and up to 5-axis capability, we can build parts to exact specifications and achieve ±.001” tolerance. Because we manufacture these parts from a wide assortment of material including mild steel, magnesium and aluminum, our primary welding process is GTAW or TIG welding incorporating both free hand and robotic welding to create clean, high-quality welds. In addition, we also use pre-heating and post-heating ovens for enhanced quality of the weldments.

To ensure part and weld integrity, we inspect the first piece in every run along with a final inspection and all weldments are tested using x-ray, fluoro penetrant inspection and mag particle inspection. Upon passing inspection, parts receive a powder coat or paint finish depending upon requirements.

We are able to manufacture 100 to 500 pieces with a typical lead-time of three to five weeks. To learn more about our production welding, or to discuss the details of a project, contact us today.

Project Examples

Production Welding Service Details

- Welding Process

-

GTAW (TIG)

- Machining

-

Large Boring Mill

Horizontal Machining Centers

Up to 5-axis

- Materials

-

- Mild Steel

Stainless Steel

Aluminum

Nickel

Magnesium

Inconel

MonelKovar

Hastelloy

Stellite

Titanium

Tool Steel (H12, D2, O2)

Non-Ferrous (4140)

- Finishes

-

Painting

Powder Coating

- Welding Operation

-

Free Hand

Robotic

- Ovens

-

Pre-Heating

Post-Heating

- Tolerance

-

± .001 in

- Inspection

-

First Piece

Faro Measuring System

Final Inspection

- Testing

-

X-Ray

Fluoro Penetrant Inspection (FPI)

Mag Particle Inspection

- Quality

-

Assurance

Traceability

- Documentation

-

Rod Lot Traceability

Certificate of Compliance

- Additional Services

-

- Burning

Finish Machining

Grinding

DrillingPressing

Sawing

Assembly

Project Management

- Production Volume

-

Experimental & Short Run Production Welding

1 to 100 pieces (Fabrication)

100 to 500 pieces (Production)

- Typical Lead Time

-

3 to 5 weeks

Rush Services Available

Additional Information

- Industry Focus

-

- Industrial

Locomotive

Military

GovernmentAppliance

Robotics

Fracking

- Intended Application

-

- Specialty Machines

Support Structures

FramesMachine Bases

Components

Train Lifts

- Certifications & Associations

-

- ISO 9001:2015 Registered

AWS (D17.1, D1.1, D2.1)

ASME (Section IX)Mil Standard

Dayton Chamber of Commerce

Dayton Region Manufacturers Association (DRMA)

- File Formats

-

AutoCAD

CAD Viewers

trwelding@prodigy.net

trwelding@prodigy.net